Our Process

We offer a range of flexible solutions and service levels, tailored to accommodate the unique needs of each client. Inspired by form, function, and cost, our systems are designed to work together, ensuring accountability and allowing us to partner with you through each phase of your project. The result is a structure that stands as a testament to the fusion of time-honored craftsmanship and modern design.

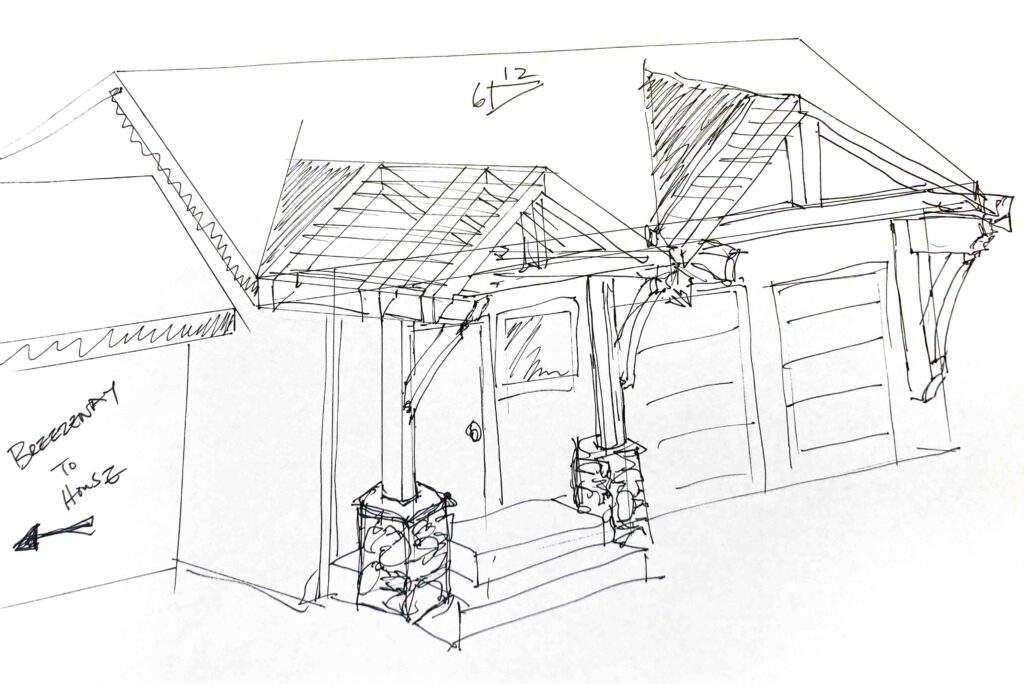

Conceptualization

We believe conceptualization requires collaboration and we want to take this time to truly get to know you. Whether you come to us with a preliminary design or are just beginning to brainstorm, we will work closely with you to develop your ideas, establish your expectations, and contemplate your budget. This collaborative dialogue informs the design process, allowing us to create a timber frame solution that aligns with our client’s vision.

Design & Engineering

Spatial Design Build employs a meticulous design process, blending traditional craftsmanship with modern innovation. Utilizing cutting-edge design software, we translate concepts into precise plans, optimizing structural integrity and energy efficiency. Engineers then conduct thorough analyses to ensure compliance with safety standards and sustainability goals. You can expect a set of schematic designs or rough construction drawings, incorporating your original design ideas, proposed materials, project parameters, and initial budget.

Fabrication

Our streamlined design path allows us to move seamlessly from project costing to production. Once construction documents are engineered and approved, our craftsmen bring the design to life, employing time-honored timber framing techniques. Using the construction documents we produce timber tallies to determine material requirements while minimizing waste and reducing overall timber cost. If not milled on-site, we source our timbers from local mills to ensure the highest quality material for the best price. The result is a harmonious fusion of artistry and engineering, reflecting the company’s commitment to quality and client satisfaction in every project.

Installation

Once the building site is prepped and fabrication is complete, the timbers are labeled and organized, streamlining the process. The same craftsmen who cut the frame will also raise it on-site, fostering a profound sense of ownership and dedication throughout the entire process. We optimize our installation process by pre-assembling key components, ready to be positioned on-site. Typically completed in under a week, this process is an exciting experience that we invite our clients to actively participate in. When it comes to installation, the saying holds: “You raise more than just a frame.”